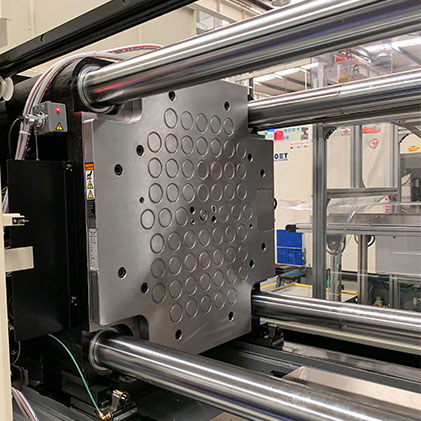

A two-color injection molding machine is specifically designed to produce molded parts using two different colors or materials in a single injection molding cycle. This type of machine has the capability to inject two different plastic materials into a mold simultaneously or sequentially to create a part with two distinct colors or materials. Magnetic clamping systems are very suitable for two-color injection molding machines. They are advanced mold clamping technology that uses magnetic force to clamp the mold, without the need for traditional mechanical clamping devices.

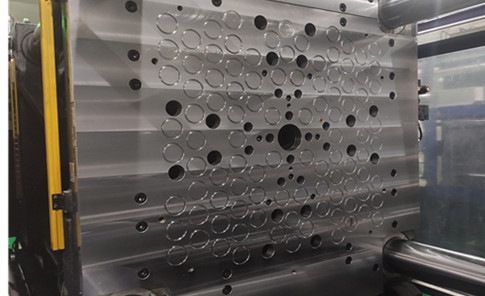

Two-color molding requires careful mold design to ensure that the convex/core side of the injection mold at the two positions is the same, and the concave/cavity side fits well with the convex/core side. The size and accuracy of the guide devices of the two molds must be consistent.

Magnetic clamping systems provide highly accurate and consistent clamping force, resulting in more precise and consistent molding results.

It's beneficial to consult with manufacturers or industry experts to get additional guidance and recommendations based on your unique circumstances. For more information, please contact HVR MAG at export@hvrmagnet.com.