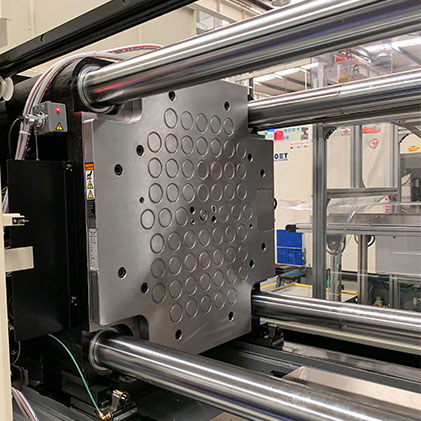

Many clients who are interested in our injection molding quick mold change system, would often pop questions like, what parameters do I have to provide for model selection of your magnetic mold clamps.

To that end, we made a list of parameters to provide for selection of magnetic mold clamps:

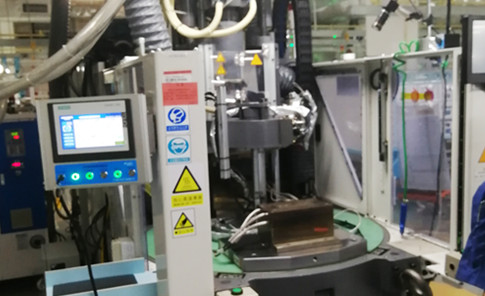

•Type/Brand/Model/Tonnage of your injection molding machineWhether it's a horizontal IMM, a vertical one, or a twin-color unit; ENGEL, Haitian, LK, YIZUMI, etc.

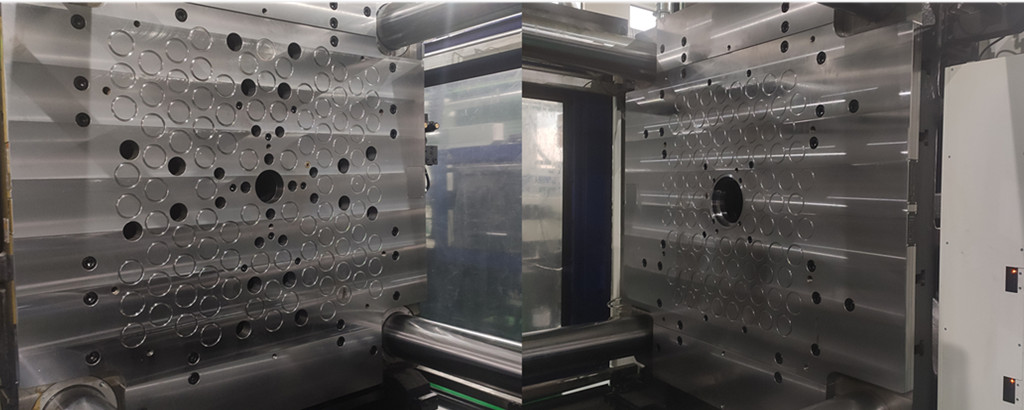

•Dimensions of Movable and fixed moulds/fixed holes;

•Diameter & height of centering rings

•Diameter & length of the ejector rod

•Mold Contact Temperature

We offer magnetic mold clamp plates with a maximum operating temperature of 120/150/180℃.

•Mold Clamping Force

We can provide magnetic mold clamps for 50-4000T injection molding machines, also for metal stamping presses.