How did your molders change mold quickly for large tonnage injection molding machines? By tightening screw and bolts, or setting up the hydraulic clamps one by one? That cannot be really quick, I think. Here, let's take a look at the following molder, changing mold for a 2300 ton IMM.

Procedures for How to Change Mold Quickly:

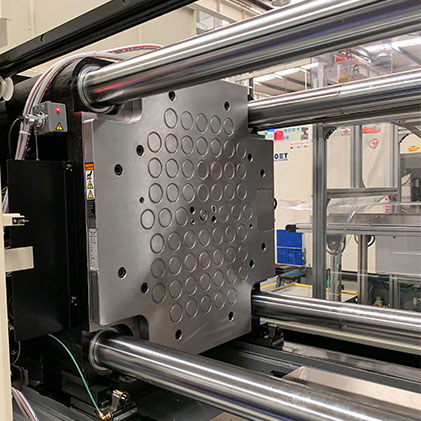

Step one, install the magnetic mold clamping plates manufactured by HVR MAG.

Step two, load the mold for next injection molding procedure.

Step three, clamp the mold via pressing buttons on interface

Step four, ready to run the machine for molding.

With our magnetic quick mold change system:

The operator no longer have to manipulate (tightening and loosening) clamps jaws manually.

No more hidden danger of oil leakage with hydraulic mold clamps.

Simple button operation, allows for quick mold lock/release.

Magnetic platens are adaptable to all injection presses and mould sizes, magnetic clamping does not require any modification of existing moulds.

How to change mold quickly, answers the need for frequent production changes. Magnetic mold clamping system is widely acclaimed for its versatility and simple implementation. This technology optimises productivity.