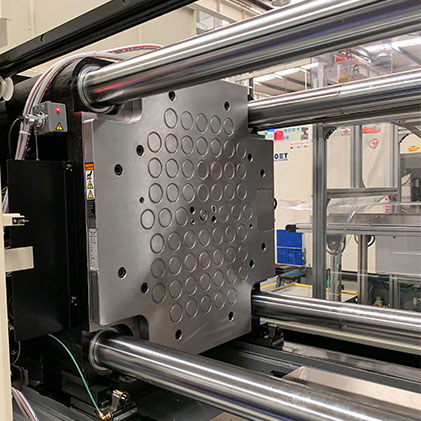

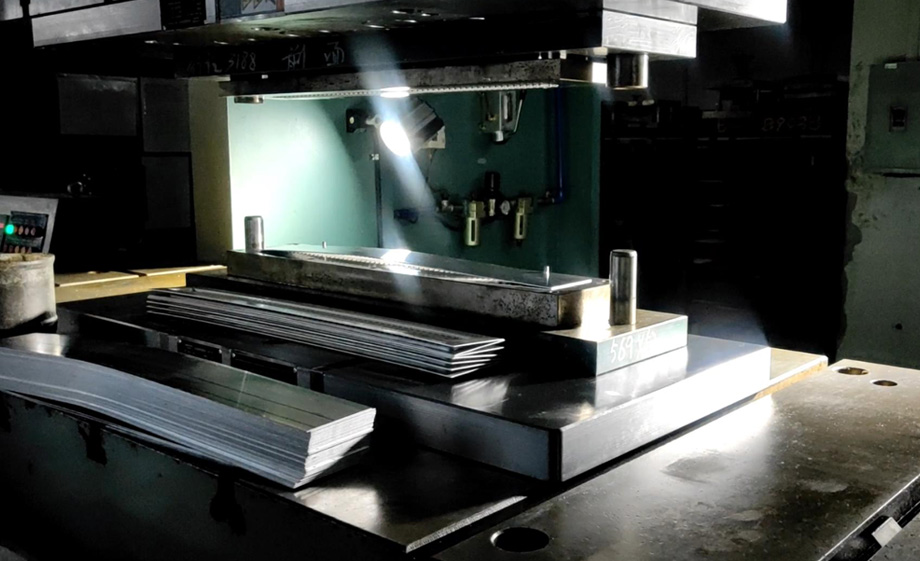

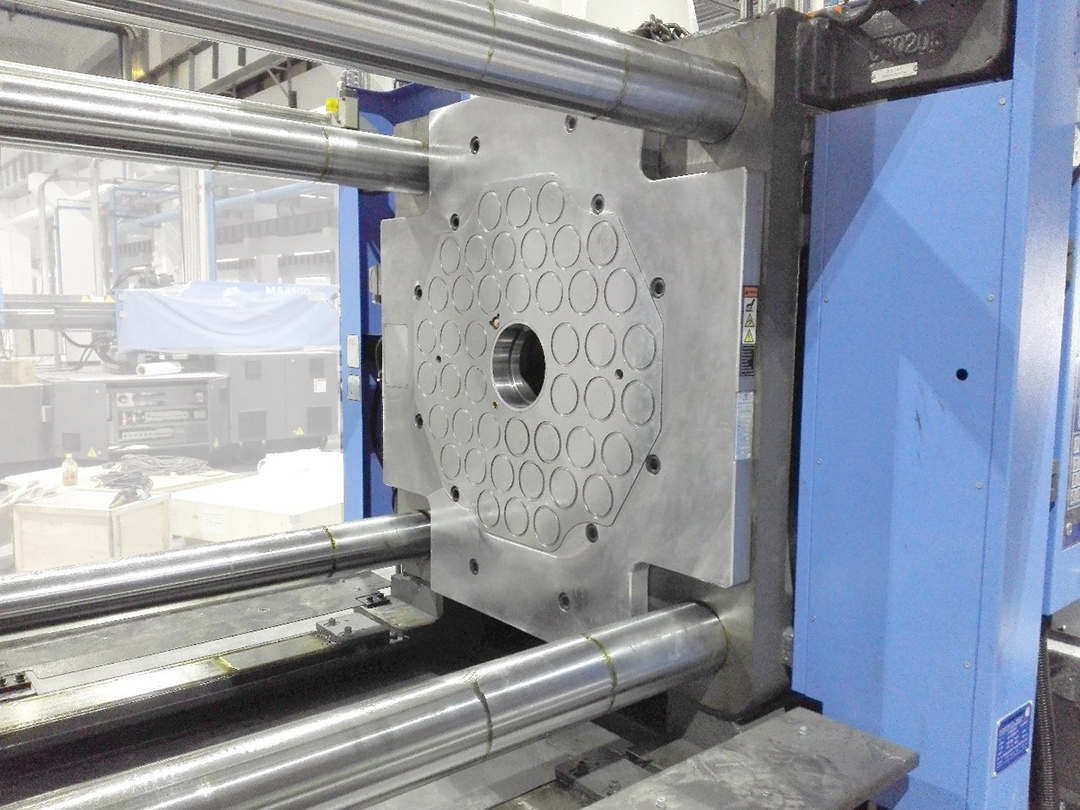

The following pictures will help you discover more about the manufacturing details of our magnetic platens to gain a better understanding of magnetic mold clamping system.

Machining of the body structure of magnetic platen, oil & water proof steel surface.

The magnetic force of HVR MAG's electro permanent magnetic platens, comes from magnet poles, the core part of 2 different types of permanent magnet materials: Neodymium and Alnico.

As a professional magnetic quick mold change solution provider, we offer magnetic platens of different voltage supply: AC220V/380V/415V/440V. The maximum operating temperature of magnetic clamping plates is 120/150/180℃. Any mold clamping questions, please feel free to contact us.