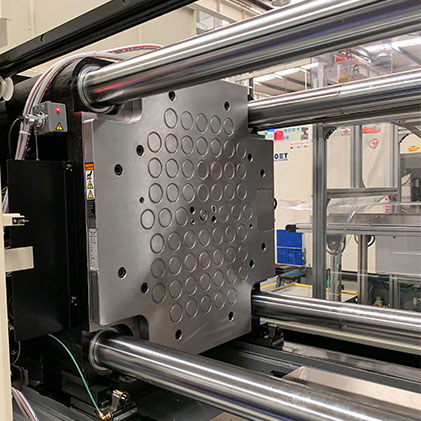

As a supplier of quick mold change solution for plastic injection molding machines, magnetic clamping system can not only greatly reduce the mold changing time for injection molding, but also can shortly shorten the machine downtime of die change process for punching presses. Below is a picture of the typical applications of magnetic platens manufactured by HVR MAG.

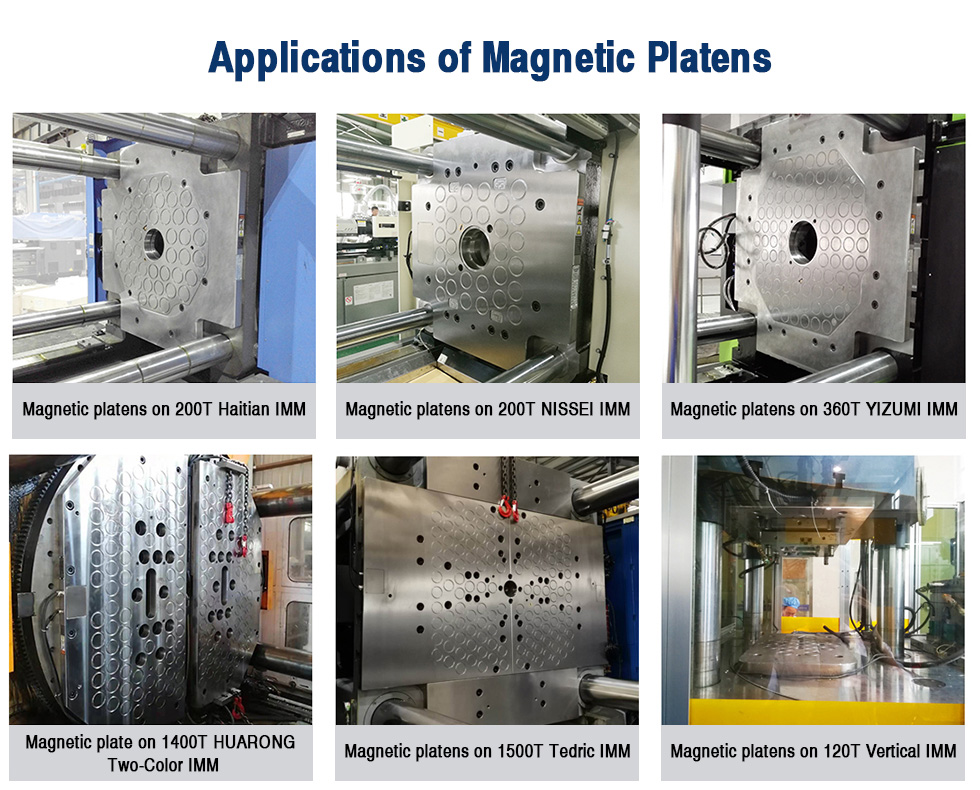

Applications of magnetic platens, can vary from small tonnage injection molding machines, to two-color IMMs, and also on vertical IMMs.

The only difference is that for normal horizontal IMMs, it often requires 2 magnetic mold clamping plates(one stationary, one movable), to be installed on eash side of the base plate of IMM; while for a two-color unit, it’s quite often that the factory only needs one magnetic plate to change mold.

The most different part of applications of magnetic platens in vertical IMMs especially the rotary type, is that it requires 2 fixed plates on the table, and 1 movable plate on upper part.