What Is Metal Stamping?

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes, which involves bending, punching, or flanking the object with a stamping press.

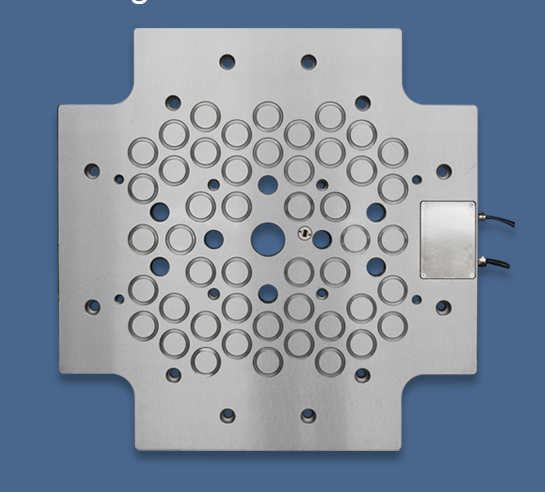

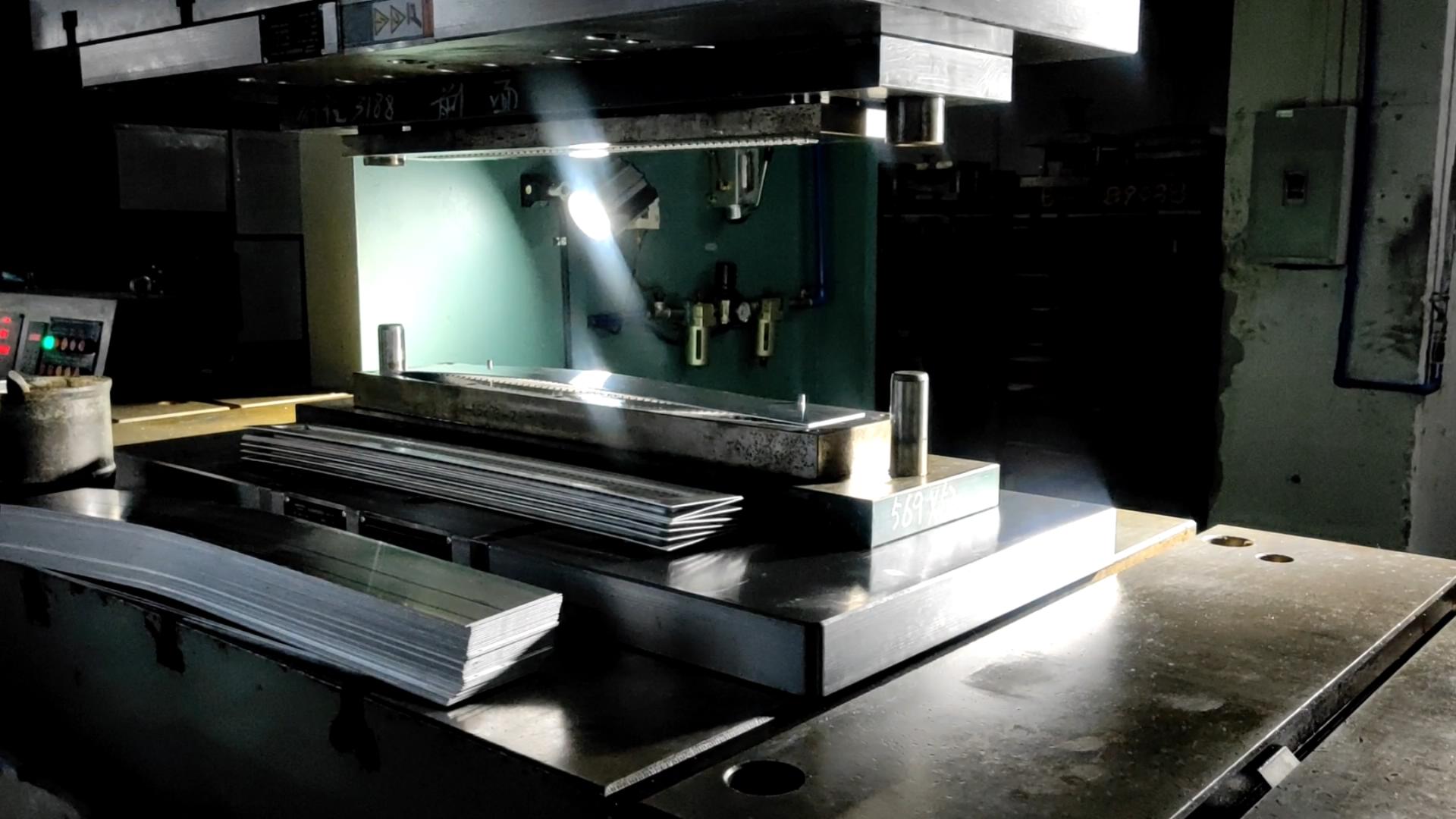

Specifications of the above Magnetic Clamping Plates

Voltage: DC 160V

Current: 8A

Power: 1.27kw

Maximum Magnetic Force: 41.2KN

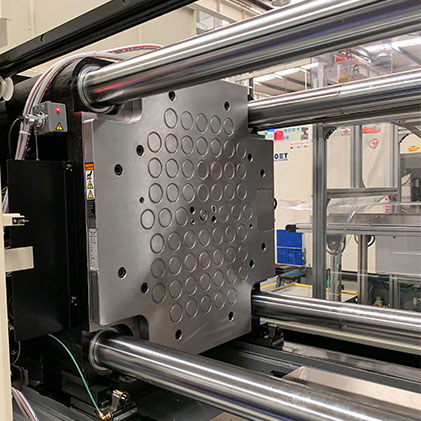

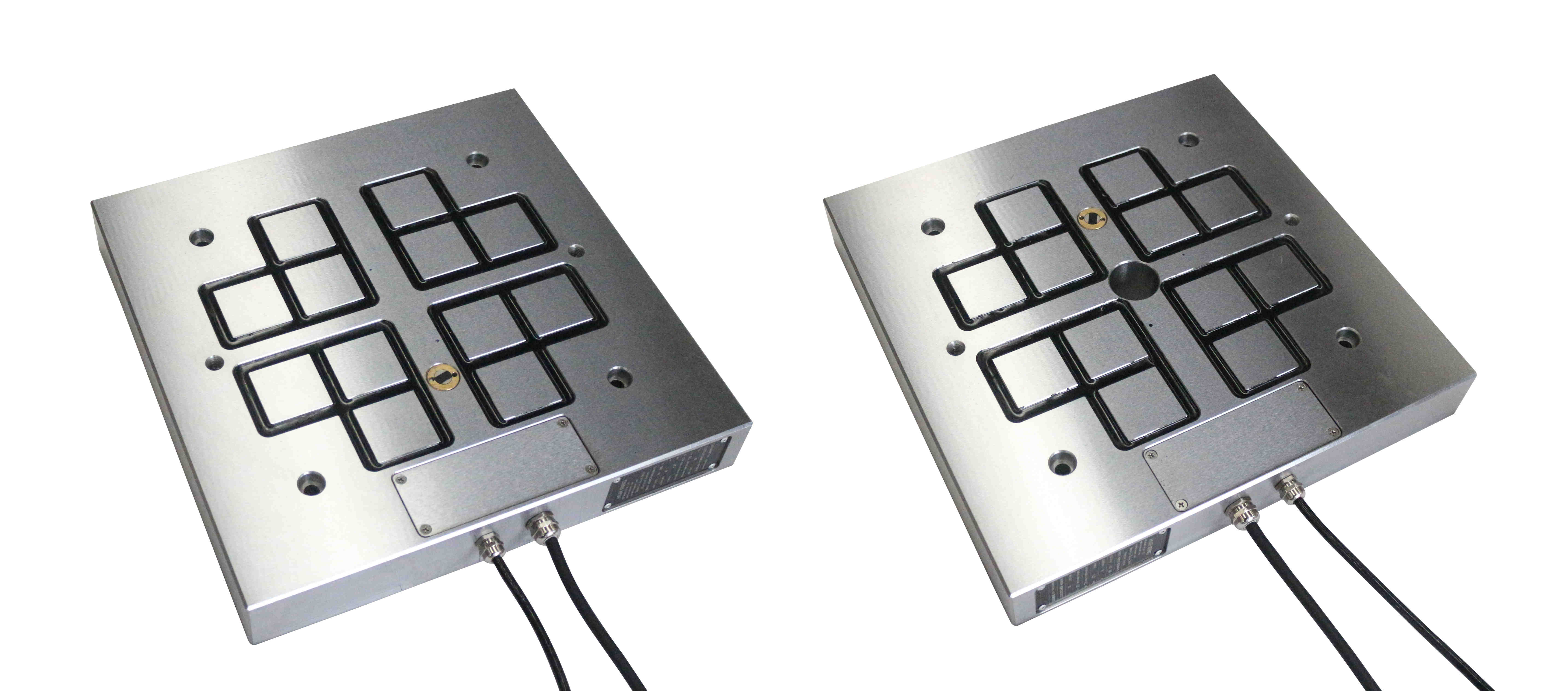

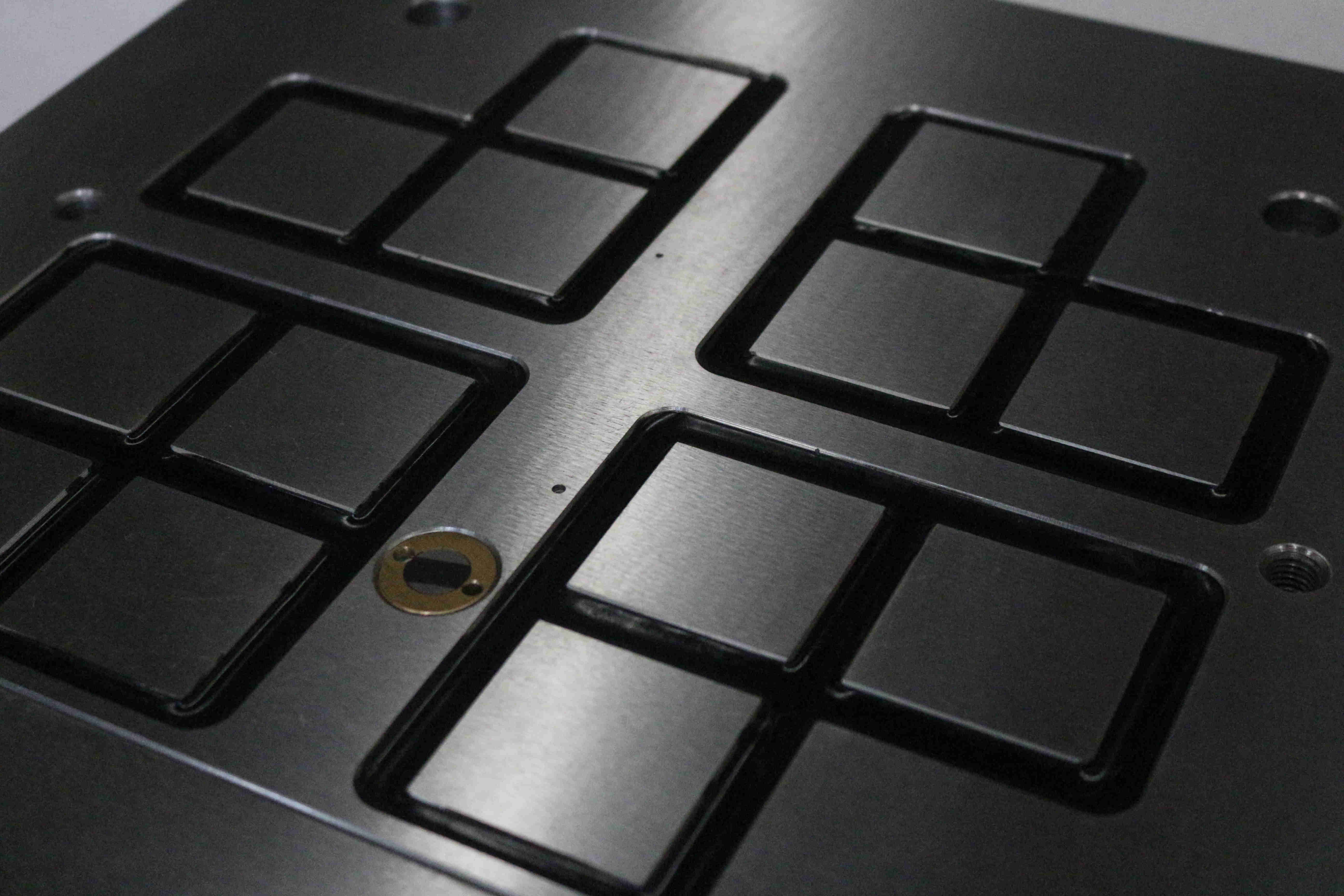

Magnetic clamping plates, are mainly used on stamping presses or punching machines, to clamp or fixate the die in the stamping process, and for a subsequent quick change of die.

How quick? The die can be changed within minutes, by simply demagnetizing the plates to release/unload the die, and magnetizing the plates to clamp/fixate the new die. It's that simple and easy.

What information do I have to provide to customize a set of magnetic clamping plates for my presses? We'll need the working voltage, current, the maximum clamping force of your press, and the minimum and maximum size of your dies. Should you have any other queries or questions about your metal stamping process, contact us for more info and help.