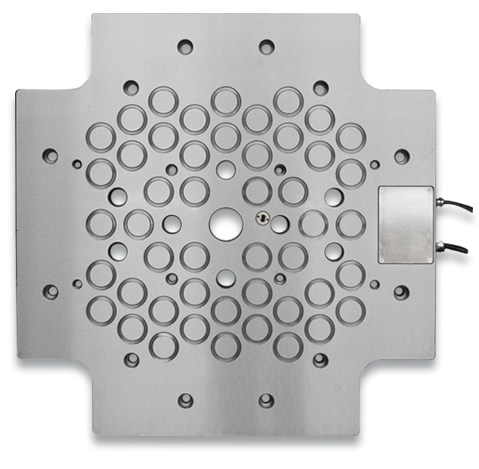

MOULD CLOSE DETECTION

The MAG cycle can only be performed when a build-up of the pressing force is detected. This ensures that both mould sizes have 100% contact with the respective magnetic plates when the MAG cycle is performed.

MAGNETIC FLUX DETECTION

Release of the machine is only given if the measured magnetic flux, after magnetization, reaches the standard minimum predefined safety value. If this is not the case, an error is indicated.

If during the injection moulding process the magnetic flux value decreases minimally, the machine stops immediately.

TEMPERATURE DETECTION

To prevent the magnetic plates against a too high temperature, which decreases the total magnetic force, the magnetic plates are equipped with a temperature sensor.

When the temperature gets higher than the pre-set value, the automatic production process stops.

CURRENT DETECTION SYSTEM

During the MAG and DEMAG cycle, the current pulse is monitored by the current detection sensor. A successful release is only reported when the set value has been reached.

MOULD DISLOCATION DETECTION

The position of the mould is monitored during the entire production. When due to circumstances a small displacement of the mould occurs, the machine stops immediately.

DISTANCE DETECTION

The proximity switch ensures that the DEMAG cycle can only be performed if the distance between the mould and the magnetic plate is less than 0.2 mm.

In addition, the automatic production process stops immediately when a distance> 0.2 mm is detected between mould and magnetic plate.

INTERFACE CONTROL SYSTEM

Only when all detection sensors are in normal operation, the fixed and movable side have been successfully magnetized, and the safety key has been placed in injection position, the automatic injection moulding process can be started. Any other condition will result in ALARM, stopping automatic operation.

SAFETY KEY

The safety key is used to select setup or automatic injection moulding mode. To execute the DEMAG-cycle, the LOCK and DEMAG buttons must been pushed simultaneously.

DEMAG is not possible during the automatic injection moulding process.