Why should rotary dual color or multi color injection molding machines have to use magnetic platen to clamp mould? Let magnetic clamping system provider HVR MAG explains to you.

Due to the speciality of the rotary table, which has to rotate 180°during the injection molding process, and that molds of different sizes have to be fixed on the rotary table, customized magnetic platen is the appropriate mold clamp, which has no restriction on mold size. Hydraulic mold clamps, however, would take up quite some space on the baseplate, which makes it inappropriate to rotate along with the machine table.

Once installed with magnetic mold clamp plate, the operator can allow fast and easy change of mold. Instead of loosening and tightening every bolt manually, the machine operator simply just need to press the buttons on the interface panel to demagnetize the platen to release the mold, and magnetize the platen to clamp the mold.

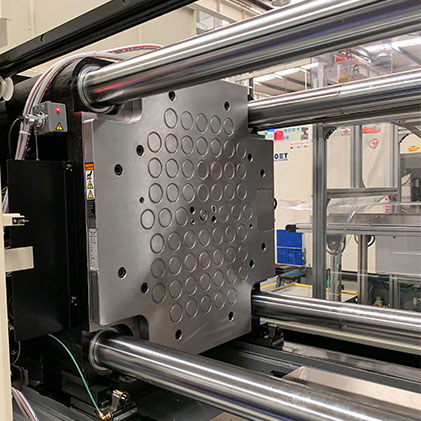

Shown in the above picture are some applications of round magnetic platen, installed on different tonnage of twin color injection molding machines. Cases are more convincing than words. Contact us for queries and solutions for your injection molding business.